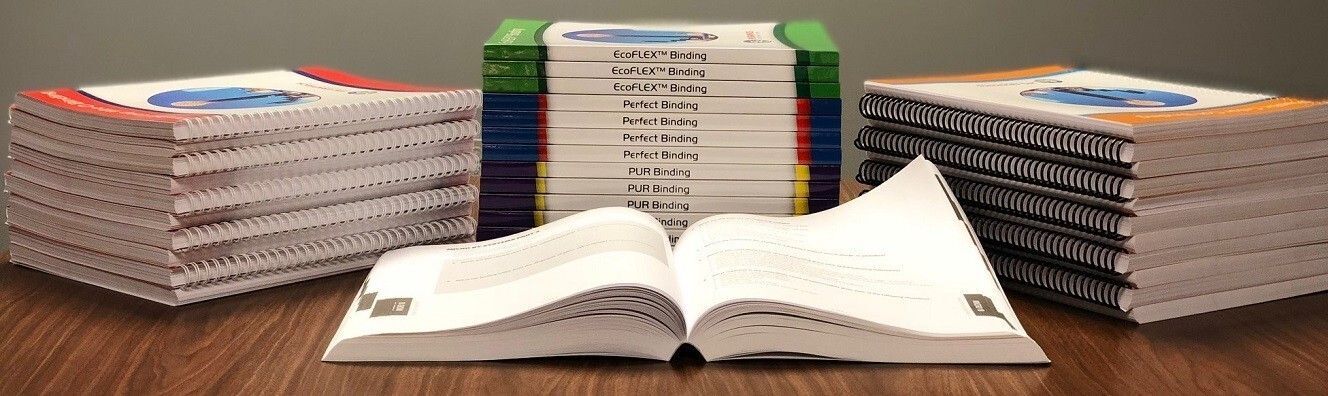

One of the first decisions you’re going to have to make when planning on your booklet binding job is the choice of the production method that you will choose to actually bind the materials together. For the uninitiated, the differences between PUR binding and Perfect binding seem like a given. If one is a stronger bind, wouldn’t it be the clear cut decision? However, the devil is in the details; the best choice is based on what your specific binding job requires.

Perfect Binding

Perfect binding was the tried and true method of book binding for many years. A classic EVA glue bind (Ethylene Vinyl Acetate), the Perfect bind is a hot melt glue process that allows for minimal waste, cost efficiency and high volume production. The pages set quickly and the speed and low-cost of the materials used make it the perfect choice for mass, soft cover binding jobs.

The tradeoff is that the Perfect bind is typically more suitable for books printed on uncoated paper. Some printing process and specialty paper combinations can be problematic. This is because the binding is held together through the glue itself. If that breaks then the integrity of the bind is forfeited. The glue will hold for its purposes, but if you’re looking to bind gloss paper you may not have the long term durability that you’d like with the Perfect binding method.

PUR Binding

The PUR bind is a different animal. A PUR bind holds via a Polyurethane Reactive adhesive that chemically binds to the pages themselves for a powerful hold. Pages in the booklet adhere to the spine and bend in a way that doesn’t compromise the integrity of the product. For coated gloss pages or case bound booklets that should last, the PUR bind is the superior choice for the job. From contents to cover, the PUR bind is effectively the strongest binding method.

The downside to the PUR bind is that the curing time of the materials takes a bit longer than the Perfect bind. Also, the materials to set the bind cost a little more to produce.

The Verdict

It’s all in what the specific booklet binding job requires. If you’re looking to get the word out quickly to as many people as possible, the speed and efficiency of a Perfect binding is the way to go. If you’re looking to show a vibrant visual with toner based digital color printing on coated stock paper, the firm adhesion of the PUR bind is what you need.

For more information in what your specific booklet binding job will require, email info@jpsgraphics.com for a free laminated Binding Comparison Chart: Choosing the Appropriate Binding.